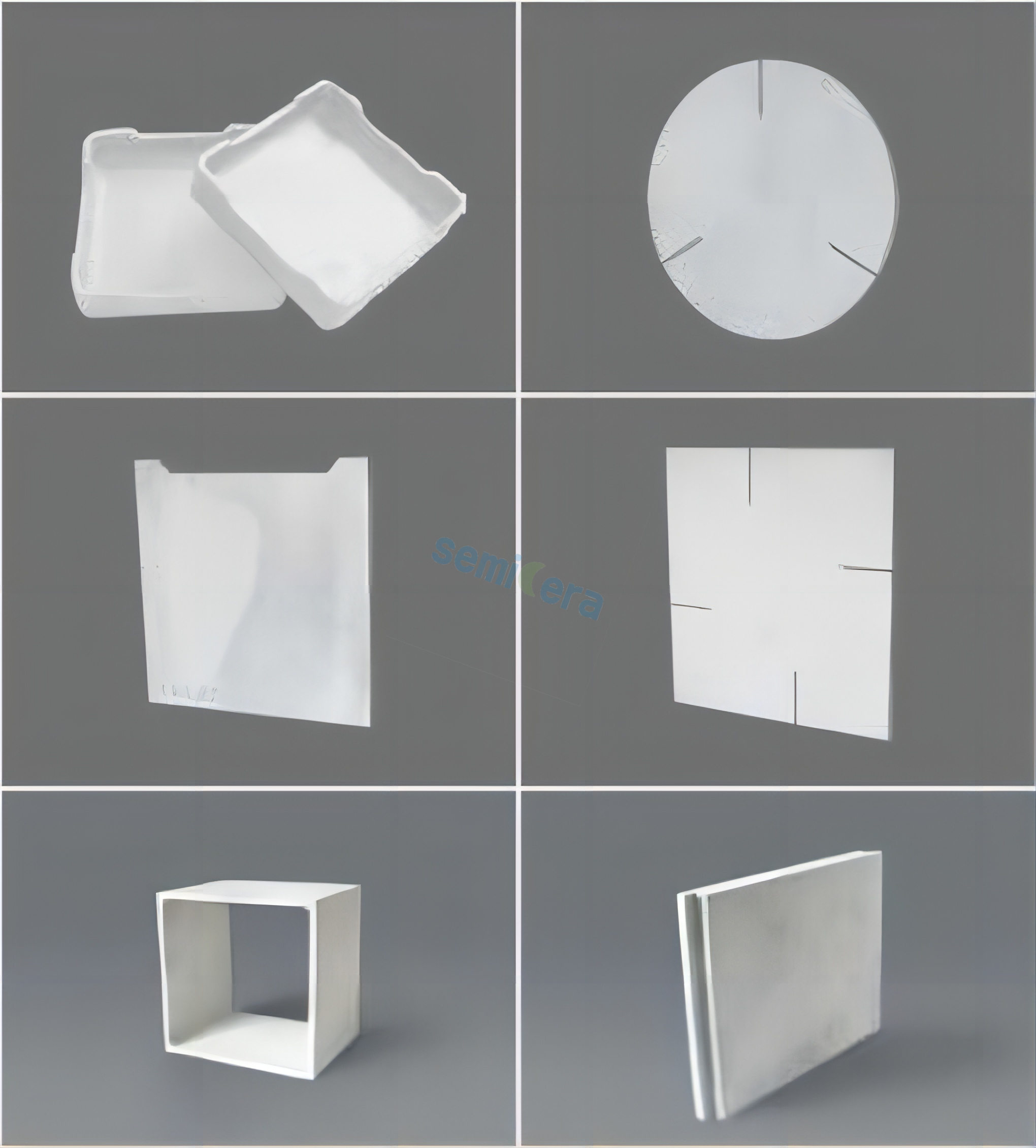

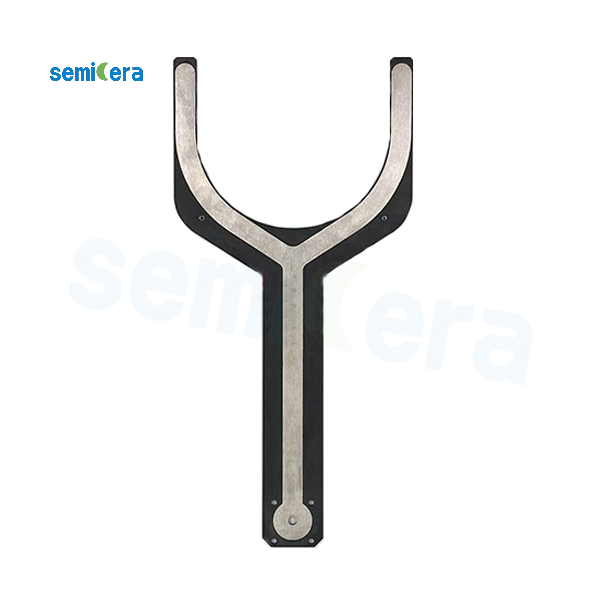

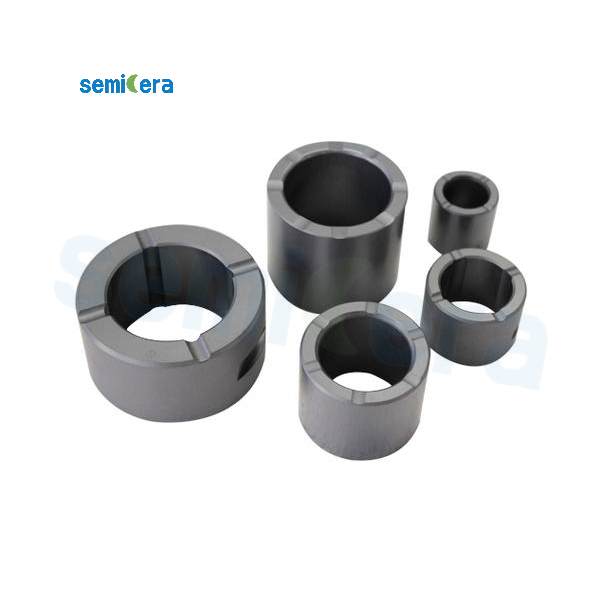

Silicon nitride conjuncta cum carbide pii furno habet proprietates caliditatis fortitudinis, bonum inpulsae scelerisque resistentiae, deformatio facilis, resistentia oxidatio, resistentia corrosio, bonum scelerisque conductivity et cetera.

Praecipua perficientur Indicatores

| Item | Firebrick index | Fornax specificatio | Index informum productum |

| Apparens poros.%. | <16 | <16 | <14 |

| mole densitatis.g/cm3. | 2 2.65 | 2 2.65 | 2 2.68 |

| Compressive vires ad locus temperatus.MPa. | 2 160 | 2 170 | 2 180 |

| Locus temperatus ad vires tendentes.1400X.. MPa | 2 40 | 2 45 | 2 45 |

| Temperatus inflexio virium.1400r. MPa | 2 50 | 2 50 | 2 50 |

| Coefficiens scelerisque expansion.110CTC.xioVC | <4.18 | <4.18 | <4.18 |

| Scelerisque conductivity.1100C. | 216 | 2 16 | 216 |

| Refractiores.°C . | 1800 | 1800 | 1800 |

| 0.2 MPa Temperatus sub onere molliens.X. | 1600 | 1600 | > 1700 |

| Maximum operating temperatus.°C. | 1550 | 1550 | 1550 |

Producti late usi sunt in rotae stridoris ceramicae, productorum aluminii altae, pilae aluminii murrinae, furni industrialis, electronici ceramici, magni voltage electrici porcellana, ware sanitaria, porcellana quotidiana, stannum nitridum et spuma ceramicorum et aliae industriae.

Indumentum resistentiae Si3N4-SiC materialis est 3.13 tempora quae ferro repugnant (Crl5Mo3), et pondus tantum 1/3 illius ferri obsistens (Crl5Mo3).

Corrosio resistentiae qualitas reductionis valorum carbidi Si3N4-SiC et calcii in variis solutionibus sunt haec:

| Test solution | Temperature("C) | Si3N4-SiC | Ceramicos communes | Aluminium carbide | Aluminium oxydatum |

| 98 %Acidum sulphuricum | 100 | 1.8 | 55.0 | > 1000 | 65,0 |

| 50 %Sodium hydroxide | 100 | 2,5 | > 1000 | 5.0 | 75.0 |

| 53 %Acidum hydrofluoricum | 25 | < 0.2 | 7.9 | 8.0 | 20,0 |

| 85 %Acidum phosphoricum | 100 | < 0.2 | 8.8 | 55.0 | > 1000 |

| 70%Acidum nitricum | 100 | < 0.2 | 0.5 | > 1000 | 7,0 |

| 45 %Potassium hydroxidum | 100 | < 0.2 | > 1000 | 3.0 | 60,0 |

| 25 %Acidum hydrochloricum | 70 | < 0.2 | 0.9 | 85.0 | 72,0 |

| 10% Acidum hydrofluoricum +57% acidum nitricum

| 25 | < 0.2 | > 1000 | > 1000 | 16,0 |