commoda

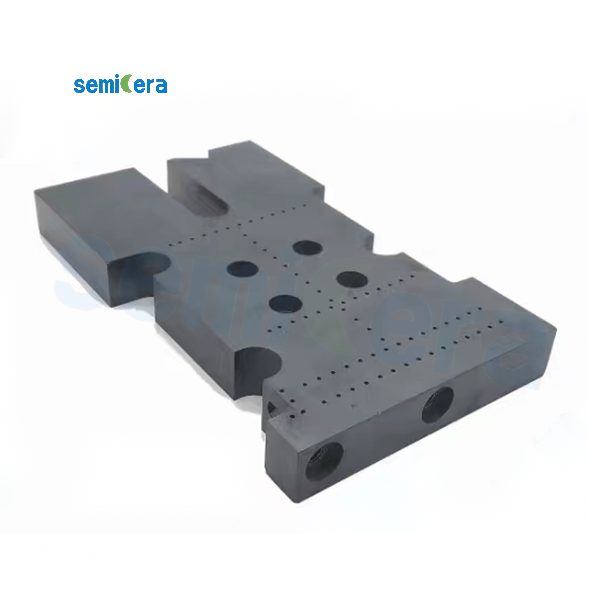

Princeps caliditas oxidationis resistentia

Corrosion resistentia praeclara

Bonum Abrasionis resistentia

Princeps coefficiens caloris conductivity

Levitas, humilis densitas

Alta duritia

Lorem amet.

Applications

-War-repugnans campus: frutex, lamina, sandblasting COLLUM, cyclus oblinit, dolium stridor, etc.

-High Temperature Field: siC Slab, Exstinguitur Fornax Tubus, Radiant Tube, Fuscus, Calefactio Elementum, Rollerus, Radius, Calor Commutator, Frigidi Aeris Pipe, Exuro Nozzle, Thermocouple Tubus, SiC Navis, Kiln Car Structura, Setter, etc.

-Silicon Carbide Semiconductor: cymba lagana SiC, sic chuck, sic paxillum, sic cassette, sic diffusio tubi, laganum furca, patella suctio, guideway, etc.

-Silicon Carbide Sigillum Campi: omnia genera signandi anulum, gerentem, fruticem, etc.

- Campus Photovoltaicus: Cantilever Paddle, Molendum Ferocactus, Silicon Carbide Rollerus, etc.

-Lithium Pugna Field

Corporalia De Proprietatibus Sic

| Property | Precium | Methodus |

| Density | 3.21 g/cc | Sink-natat et dimensio |

| Imprimis calor | 0.66 J/g °K | Pulsus mico laser |

| Flexurae vires | 450 MPa560 MPa | 4 punctum anfractus, RT4 punctum flexus, 1300° |

| Fractura spissitudo | 2.94 MPa m1/2 | Microindentation |

| duritia | 2800 | Vicker's, 500g onus |

| Elasticus ModulusYoung's Modulus | 450 GPa430 GPa | 4 pt flecti, RT4 pt flecti, MCCC °C |

| Frumenti magnitudine | 2 – 10 µm | SEM |

Scelerisque Proprietatibus SiC

| Scelerisque Conductivity | 250 W/m °K | Modus laser mico, RT |

| Scelerisque Expansion (CTE) | 4.5 x 10-6 °K | Locus temp ad 950 °C, silica dilatometer |

Technical Parameters

| Item | Unitas | Data | ||||

| RBSiC(SiSiC) | NBSiC | SSiC | RSiC | OSiC | ||

| SiC content | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Liberum Pii content | % | 15 | 0 | 0 | 0 | 0 |

| Max ministerium temperatus | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Density | g/cm*3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Apertum poros | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Tendens vires 20℃ | pa | 250 | 160 | 380 | 100 | / |

| Tendens robur 1200℃ | pa | 280 | 180 | 400 | 120 | / |

| Modulus elasticitatis 20℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus elasticitatis 1200℃ | Gpa | 300 | / | / | 200 | / |

| Scelerisque conductivity 1200℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Coefficiens scelerisque expansion | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

CVD carbida siliconis in superficie exteriore productorum carbidi siliconis ceramici recrystallized potest attingere puritatem plus quam 99,9999% ut obviam necessitatibus clientibus in industria semiconductoris.